Scotch-Brite™ Roloc™ Surface Conditioning Disc SE-DR, 76 mm, A CRS, Brown

- 3M ID 7000042733

- UPC 00048011180823

Details

Highlights

- Course, tough non-woven disc aggressively deburrs and finishes

- Open-web construction resists loading and runs cool, producing consistent finishes

- Conformable disc conditions surfaces without gouging, undercutting, or damaging the base material

- Convenient 3M™ Roloc™ attachment system offers quick and easy disc change-out for multi-step finishing processes

- Convenient 3M™ Roloc attachment system provides quick and easy disc change-out

- POWERED BY ALUMINUM OXIDE: Take advantage of aluminum oxide with its high cut-rate, hardness and strength

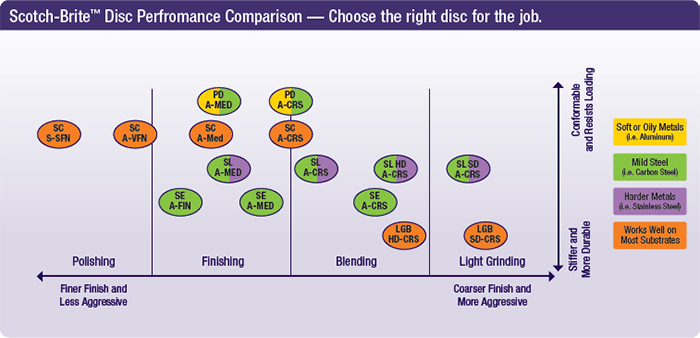

- AVAILABLE IN A RANGE OF GRADES: Fine (FIN), Medium (MED) and Coarse (CRS) to fit your application needs

Scotch-Brite™ Roloc™ SE Surface Conditioning Disc combines a coarse, non-woven disc to perform heavy-duty deburring and finishing with the efficiency of the 3M™ Roloc™ quick-change attachment system. Our heavy-duty non-woven fiber construction conforms well to help preserve irregular or contoured surfaces and our Roloc™ backing supports the disc to allow for aggressive cutting.

Suggested applications

- Use for heavy duty deburring and finishing

- Suitable for use on a wide range of substrates in both woodworking and metalworking, including ferrous alloys

Typical Properties

Resources

Connect with us. We’re here to help.

Send Us a Message

Thank you for your interest in 3M. In order to help us manage and respond to your query effectively, we politely ask you to provide some key information, including your contact details. The information you provide will be used to respond to your request through email or telephone by a 3M representative or one of our authorised business partners with whom we might share your personal information consistent with the 3M privacy policy

Thank you for your contacting 3M

We have received your message and are now looking into your enquiry

One of our representatives will get in touch with you by phone or email