Scotch-Brite™ Surface Conditioning Low Stretch Roll

- | Select product options for IDs.

Details

Highlights

- Available in a variety of sizes and grades to meet various project requirements

- Color coded by grade to reduce risk for error

- Works well on metal, plastics and composites

- Open web responds to surface irregularities while minimizing the geometry alteration on the part

- Open web responds to surface irregularities while minimizing the geometry alteration on the part

- Stiffer backing has less stretch on high tension applications

Our Scotch-Brite™ Surface Conditioning Low Stretch Roll effectively blends, deburrs, finishes and cleans a variety of substrates. It can also be used for light grinding. The versatility of the Scotch-Brite™ Surface Conditioning Low Stretch Roll makes it a good all-purpose product.

Non-woven material combined with abrasive grain is an ideal way to add a great finish or remove burrs without gouging or undercutting the workpiece

Our Scotch-Brite™ Surface Conditioning Low Stretch Roll has all the benefits operators expect from Scotch-Brite™ products, including non-woven technology and a uniform cut. The low-stretch backing sets it apart. A low-stretch, reinforced backing keeps the abrasive side taut and firm as it abrades the surface.

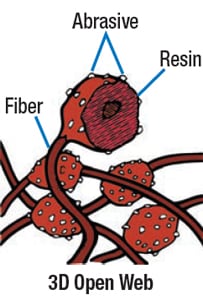

Benefits of Open Web

Non-woven technology makes our Scotch-Brite™ abrasives unique. We intersperse abrasive mineral on synthetic fibers using resin — creating an open web construction. Spaces between the fibers permit excess material to escape, so the mineral does not get worn down by debris. It keeps the mineral cutting sharper longer, enhancing cut performance and increasing abrasive service life. The spring-like nature of the fibers works well on contours and responds to subtleties on the surface. Its responsive design effectively removes unwanted burrs, soils and contaminants without ruining the base material, so you get a consistent and uniform finish — part after part.

Suggested applications

- Use for cleaning, polishing and finishing

Typical Properties

Resources

Connect with us. We’re here to help.

Send Us a Message

Thank you for your interest in 3M. In order to help us manage and respond to your query effectively, we politely ask you to provide some key information, including your contact details. The information you provide will be used to respond to your request through email or telephone by a 3M representative or one of our authorised business partners with whom we might share your personal information consistent with the 3M privacy policy

Thank you for your contacting 3M

We have received your message and are now looking into your enquiry

One of our representatives will get in touch with you by phone or email