3M™ Trizact™ Cloth Belt 363FC

- | Select product options for IDs.

Details

Highlights

- Trizact™ abrasives can last up to five times longer than conventional abrasives

- Waterproof polyester YF-weight backing allows users to rinse the belt – reducing clogging of the abrasive

- Resin bond helps to resist thermal and chemical deterioration

- Improves finish consistency and part to part size

- Improved part-to-part size

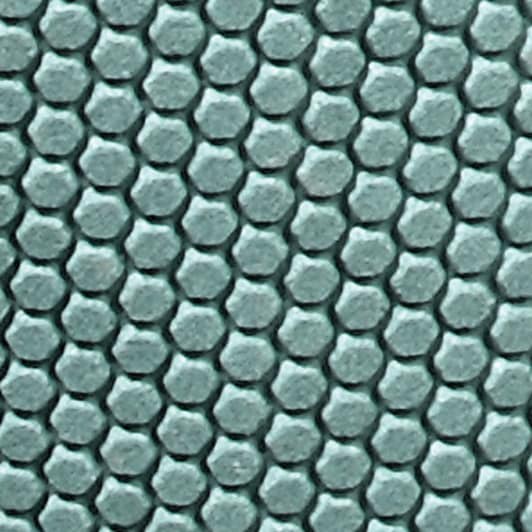

3M™ Trizact™ Cloth Belt 363FC features an aluminium oxide mineral bonded to a YF-weight polyester cloth backing. Our 363FC belts are available in grades A300 to A35.

| Sequential Surface Finishes Obtained Ra (micro inch) Target Removal (inches off the diameter) |

|||||||

| Roll Material | A300 | A160 | A100 | A65 | A45 | A35 | |

| Mild Steel | Ra Target Removal |

60-70 0.010-0.015 |

55-65 0.005-0.0075 |

40-50 0.005 |

30-35 0.004 |

20-25 0.0025 |

12-18 0.001 |

| Operating Conditions | Recommended | Acceptable Range |

| Belt Speed (SFPM) | 6,000 | 4,000-7,000 |

| Workpiece Speed | 75 | 50-150 |

| Traverse Rate | 1/4 inch/rev | 1/10-1/2 inch/rev |

| Contact Wheel | Incompressible Aluminum, Steel, Polymer; 1/4" wider than abrasive belt | |

| Alternate Contact Wheel | 90 Shore A, smooth or serrated | |

| Coolant | Water with 4-8% synthetic coolant | |

3M™ Trizact™ Cloth Belt 363FC is available in grades from A300 to A35

A resin bond helps to resist thermal and chemical deterioration, which can occur during sanding. This bond is very tough and excellent for precision work on hard and soft surfaces. This also allows for faster sanding and a higher cut rate. The waterproof polyester backing material enables the user to rinse areas of the workpiece and the belt during use to prevent dust and debris from clogging the points of the abrasive, while producing a faster cut at the same time.

The Trizact Promise

Unlike conventional abrasives, 3M™ Trizact™ products start sharp and stay sharp, resulting in more predictable finishes and improved, consistent quality. Layers of abrasive mineral precisely distributed across the backing provide resilience and eliminate product to product variation. 3M™ Trizact™ belts last longer than conventional abrasive belts and provide such precise finish control that operators can reduce grade sequences, requiring fewer process steps and fewer abrasive products.

Trizact Consistency and Belt Versatility for Base Steel Dimensioning

We combined the unmatched consistency of our Trizact abrasives with the ease and versatility of a belt dimensioning process for fast, predictable results on stainless, mild and hardened steel. Grade A300 provides quick cutting and accurate dimensioning of base metal prior to thermal spray coating. Proceed to achieve finer finishes by through simple belt changes to the appropriate abrasive grade.

Suggested applications

- For wet grinding, finishing and polishing of carbon steel, stainless steel, nickel alloys zirconium and titanium parts in centreless as well as flat finishing applications

Typical Properties

Resources

Connect with us. We’re here to help.

Need help finding the right product for your project? Contact us if you need product, technical or application advice or want to collaborate with a 3M technical specialist

Send Us a Message

Thank you for your interest in 3M. In order to help us manage and respond to your query effectively, we politely ask you to provide some key information, including your contact details. The information you provide will be used to respond to your request through email or telephone by a 3M representative or one of our authorised business partners with whom we might share your personal information consistent with the 3M privacy policy

Thank you for your contacting 3M

We have received your message and are now looking into your enquiry

One of our representatives will get in touch with you by phone or email

3M™ Trizact™ Cloth Belt 363FC

3M™ Trizact™ Cloth Belt 363FC 3M™ Air Powered File Belt Sander, 13 mm x 457 mm

3M™ Air Powered File Belt Sander, 13 mm x 457 mm